Efficient Lift Breakdown Solutions: What to Expect from Top Lift Repair Solutions

Efficient Lift Breakdown Solutions: What to Expect from Top Lift Repair Solutions

Blog Article

Lift Maintenance Repair

Elevator Suite Britannia Street Tividale B69 2PG

01926 266127

In-depth Evaluation on Common Problems and Solutions in Lift Repair Work

In the realm of lift fixing, a careful examination of typical concerns and their equivalent remedies is critical to making sure the seamless procedure and security of these crucial upright transport systems. From the troublesome issues with lift doors to the intricate complexities of electric malfunctions, a myriad of difficulties can plague lift capability (lift breakdown). As we dive right into the ins and outs of elevator maintenance, a detailed understanding of these issues and the effective methods for fixing them emerges as a vital facet of guaranteeing optimal lift efficiency

Elevator Door Issues

Among one of the most common obstacles run into in lift upkeep is attending to lift door breakdowns. The smooth operation of elevator doors is vital for traveler safety and security and performance. A defective door can lead to hold-ups, trouble, and also prospective threats.

Lift door issues can come from different variables, such as damaged door sensing units, misaligned doors, worn-out rollers, or issues with the door operator mechanism. These malfunctions can cause doors not opening up or closing correctly, getting stuck midway, or even closing too rapidly, posing a threat to passengers going into or leaving the lift.

To address lift door breakdowns successfully, upkeep professionals need to conduct normal evaluations, oil relocating parts, change door timings, and replace damaged components promptly. Furthermore, executing preventive upkeep timetables can aid identify and solve potential door problems before they intensify. By prioritizing lift door maintenance and quickly attending to malfunctions, building owners can ensure the safe and reliable operation of their lifts.

Electrical Malfunctions

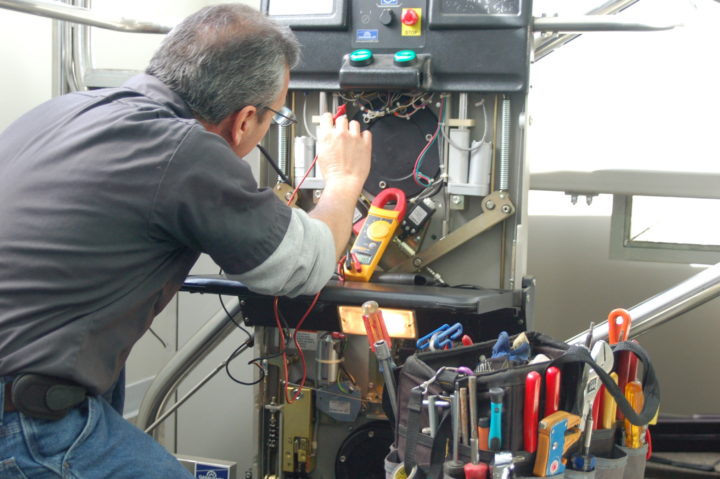

Addressing electrical breakdowns in lifts needs comprehensive analysis evaluations and exact troubleshooting methods to ensure the trusted and safe functioning of the lift system. Electrical malfunctions can materialize in numerous ways within a lift system, varying from issues with the control panel, defective electrical wiring, power supply troubles, to troubles with interlocks and sensing units. When coming across electric breakdowns, it is crucial for upkeep employees to follow a methodical approach. This consists of examining the power supply to the lift, checking electrical wiring for any type of signs of damages or wear, and examining the functionality of essential elements such as the control board and emergency situation quit switch. Utilizing diagnostic devices such as multimeters and circuit testers can help in identifying the source of the electrical malfunction properly. In addition, making sure that all electric links are safe and up to code is essential in stopping future malfunctions. By attending to electric problems promptly and successfully, lift professionals can weblink maintain the safety and performance of elevator operations.

Hydraulic System Troubles

Moreover, hydraulic pump failings can happen as a result of problems such as overheating, excessive wear, or lack of proper maintenance. A malfunctioning pump can lead to the lift not being able to produce enough hydraulic pressure to operate successfully. Routine inspection, upkeep, and prompt replacement of hydraulic elements can stop these issues and ensure the smooth performance of the click this link lift system. Appropriate training for maintenance employees on hydraulic system fixing and repair service can also aid in attending to these problems without delay and successfully.

Control System Problems

Control system malfunctions can disrupt the smooth procedure of lift systems and present safety risks if not immediately addressed. These problems often stem from problems such as electrical failures, software insects, or sensor breakdowns. When the control system falls short to interact successfully with the lift elements, it can cause unpredictable activities, unforeseen quits, or full shutdowns. One typical trouble is the imbalance of sensing units, leading to unreliable flooring progressing and door procedures. Electrical failures, including power rises or harmed electrical wiring, can additionally create the control system to breakdown.

To address control system glitches, lift repair work specialists need to perform thorough diagnostics to pinpoint the source of the concern. This may include testing the electrical connections, adjusting sensing units, or reprogramming the control software application. Regular upkeep checks can aid protect against these problems by recognizing possible concerns prior to they rise (lift repair). By promptly addressing control system malfunctions, lift drivers can guarantee the safety and security and dependability of their systems for travelers and stop costly downtime.

Safety Includes Concerns

In making sure the optimum functionality of lift systems, vigilance in the direction of the honesty of security functions ends up being critical complying with the identification and resolution of control system glitches. Security functions in lifts are made to avoid accidents, injuries, and breakdowns. Resolving safety and security attribute issues quickly can substantially decrease the risk of accidents and improve the total safety and security of lift procedures.

Conclusion

In final thought, usual problems in lift repair consist of elevator door concerns, electric breakdowns, hydraulic system troubles, control system glitches, and safety and security attributes problems. It is vital for upkeep teams to deal with these concerns quickly to guarantee the safe and efficient operation of elevators. By carrying out correct maintenance methods and regular assessments, these problems can be identified and dealt with effectively to avoid any disruptions in elevator function.

In guaranteeing the optimum functionality of lift systems, vigilance in the direction of the honesty of safety attributes ends up being vital adhering to the recognition and resolution of control system see here glitches - lift servicing companies.In verdict, usual issues in lift repair service include lift door issues, electrical malfunctions, hydraulic system problems, control system problems, and security attributes issues

Report this page